Background

Hand-pump purifiers are slow, they fail to remove many waterborne viruses, bacteria and protozoa. Grayl makes clean drinking water in seconds, allowing users to tap into the world’s water sources and safely drink from spigots, hotel sinks, murky rivers, wells or lakes.

I was the standalone designer from concept to volume production with the following objectives:

- Increase capacity from 16oz to 24oz.

- Improve filter swap user experience.

- Prevent damage when dropped.

- Eliminate lid contamination risk.

Benchmarking

Extensive outdoor testing over several weeks revealed the product’s primary pain points. Comparing these with feedback and reviews, I identified key aspects of the design to improve.

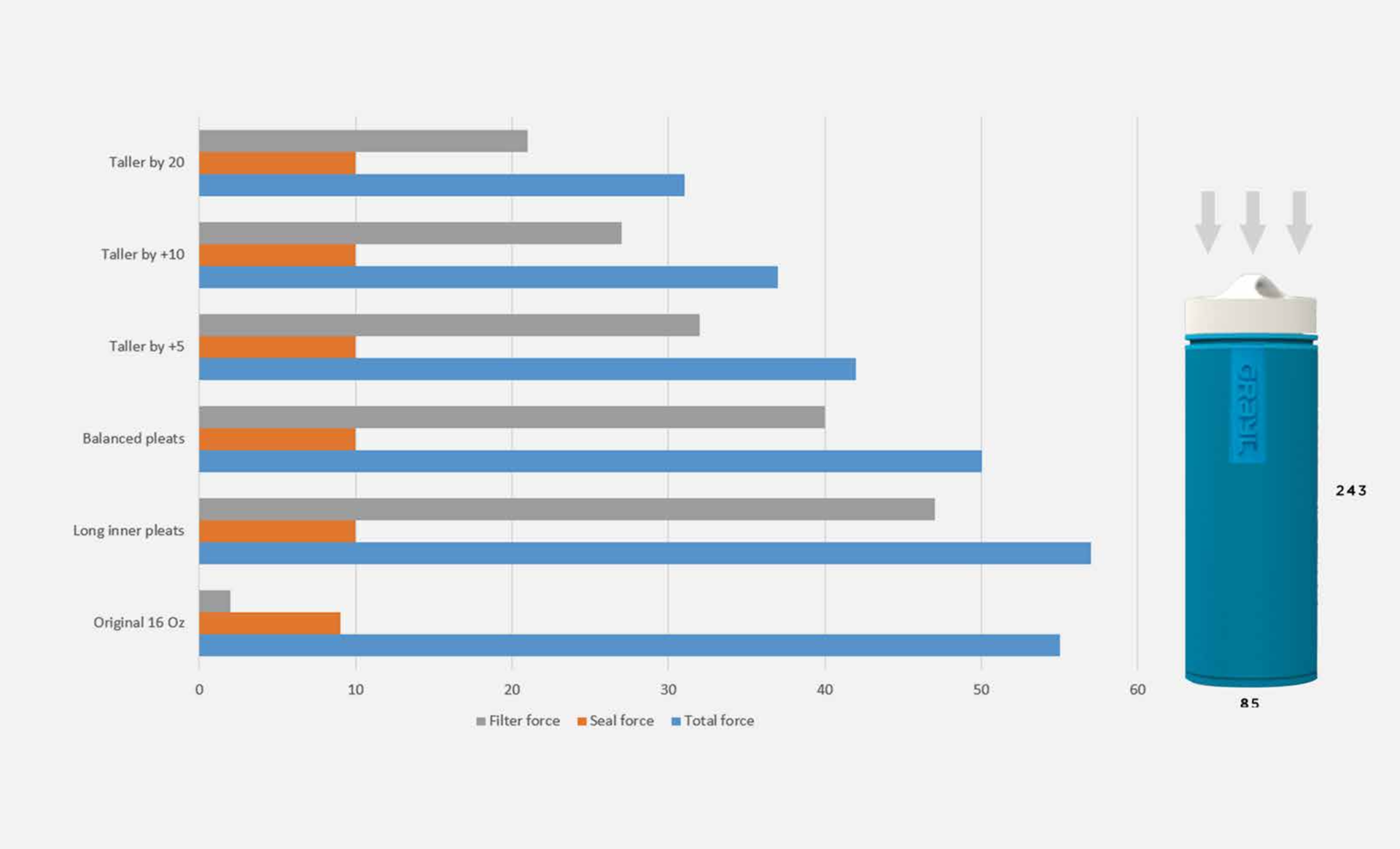

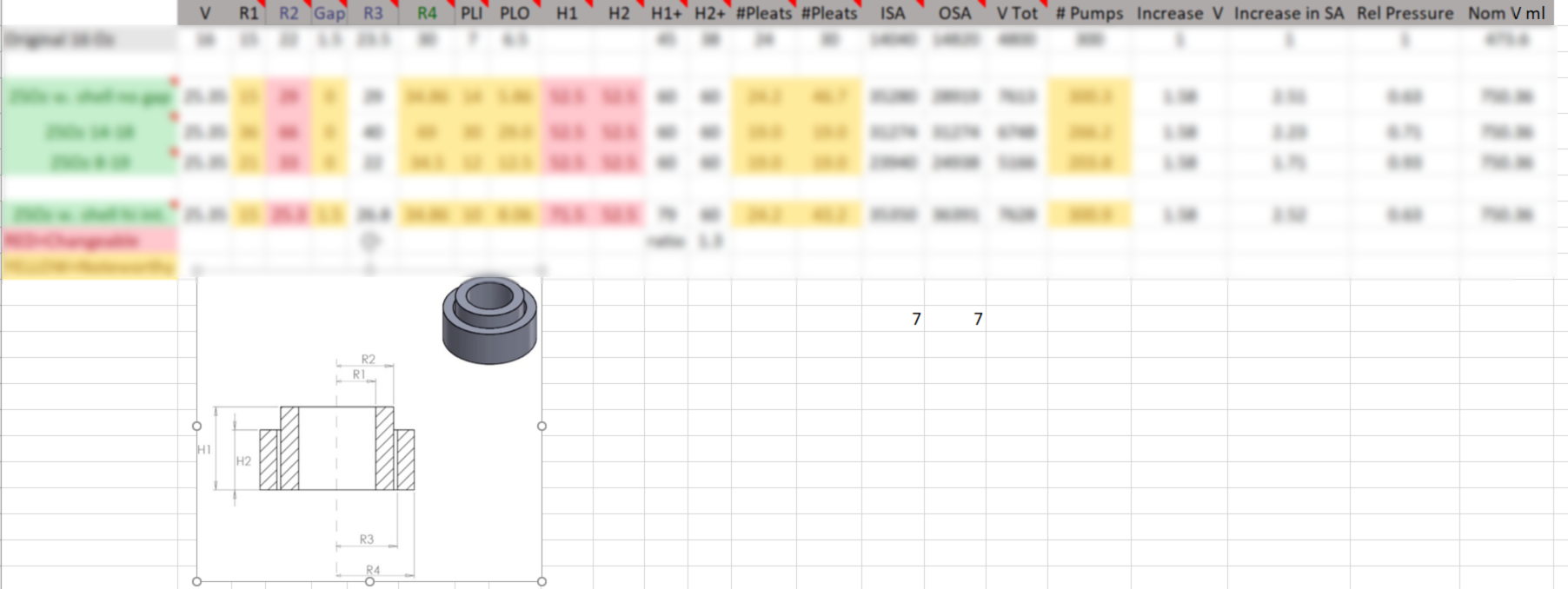

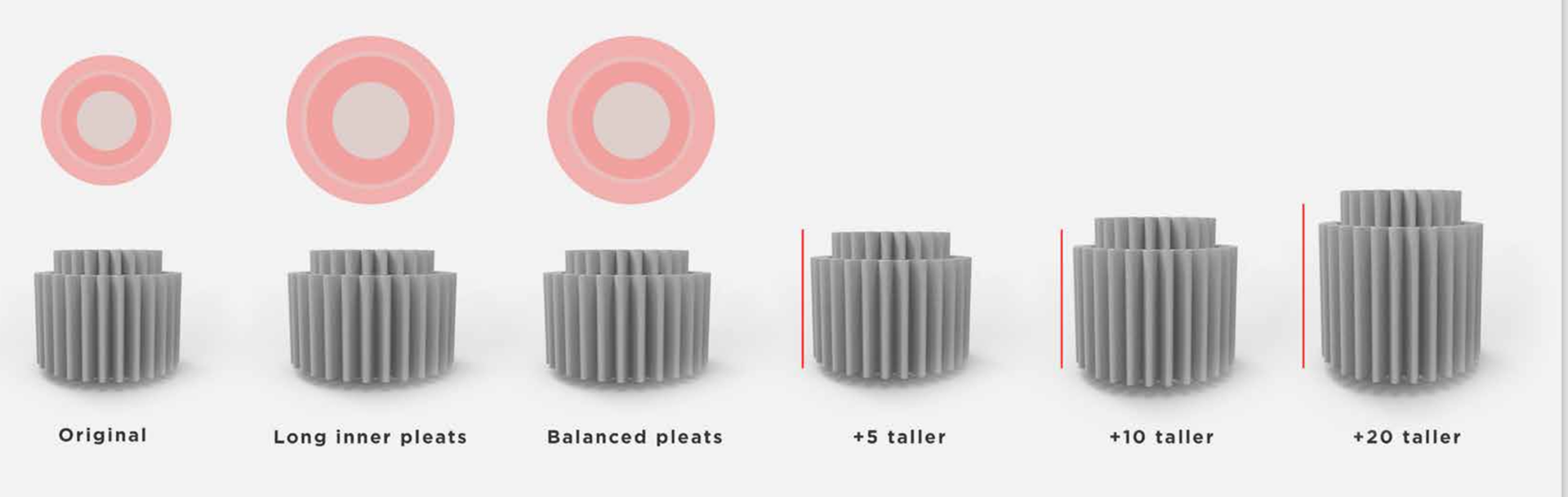

I designed an equation to optimize filtration media, resulting in an enhanced filtration flow rate and reduced pressing force. This made it easier and faster for users to press the bottle with their palms.

Design Development

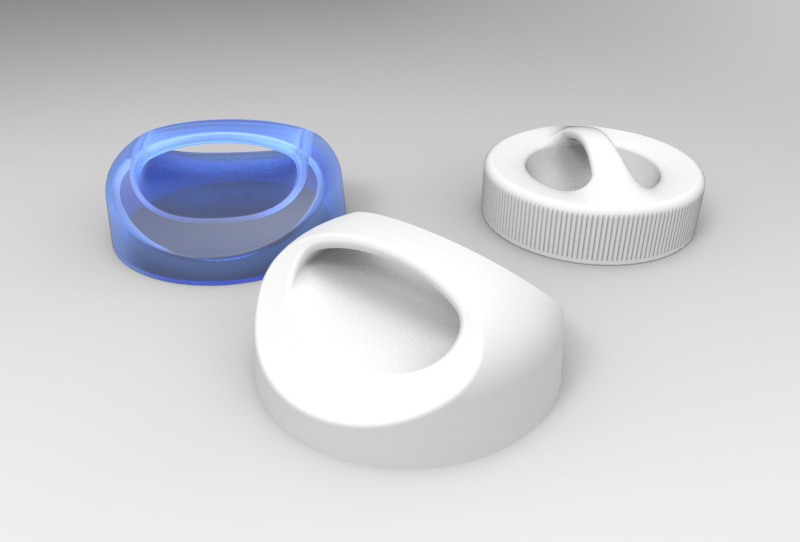

User research revealed two issues with the original design: contamination while pressing the lid, and an ergonomically challenging filter swap.

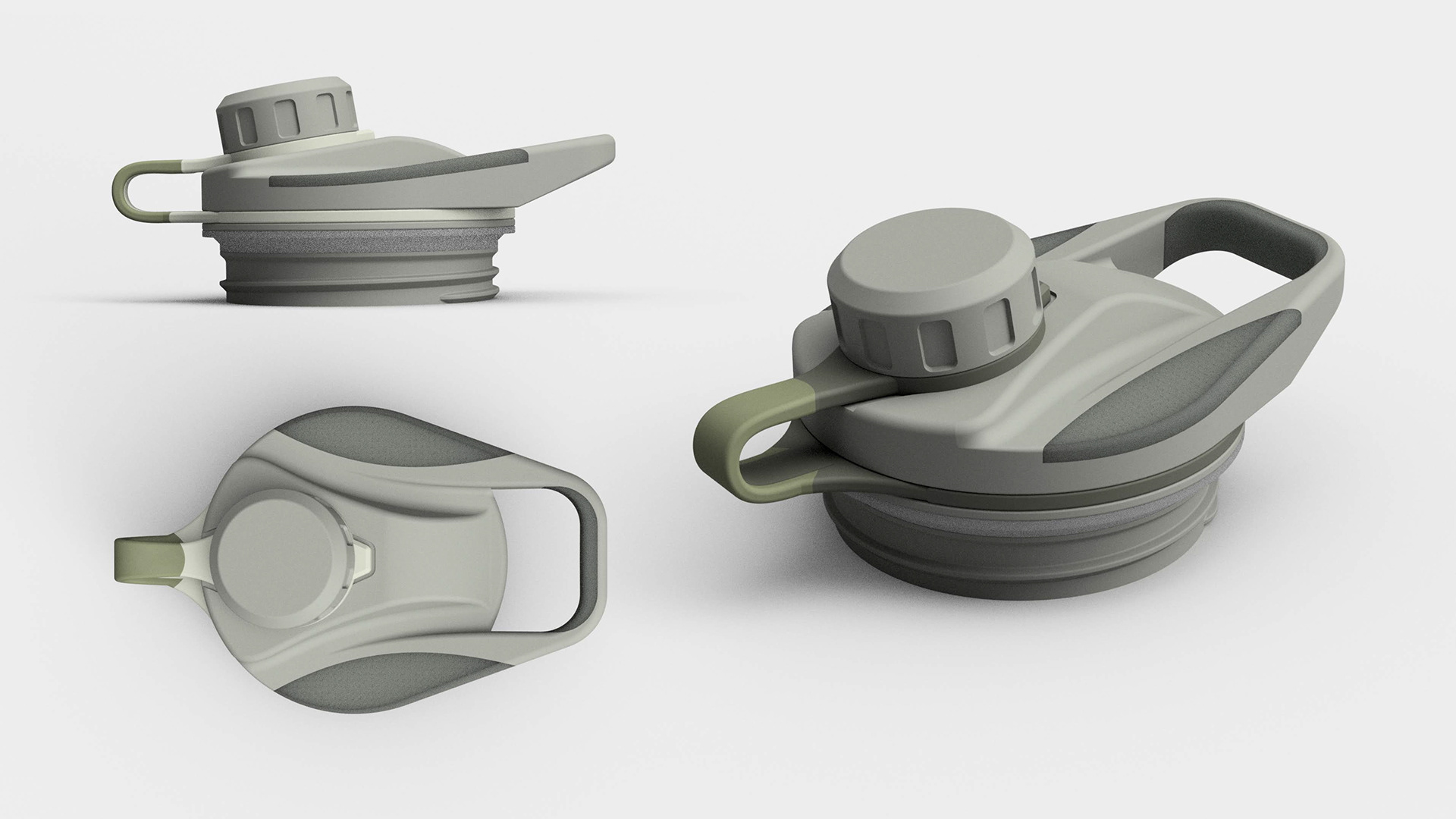

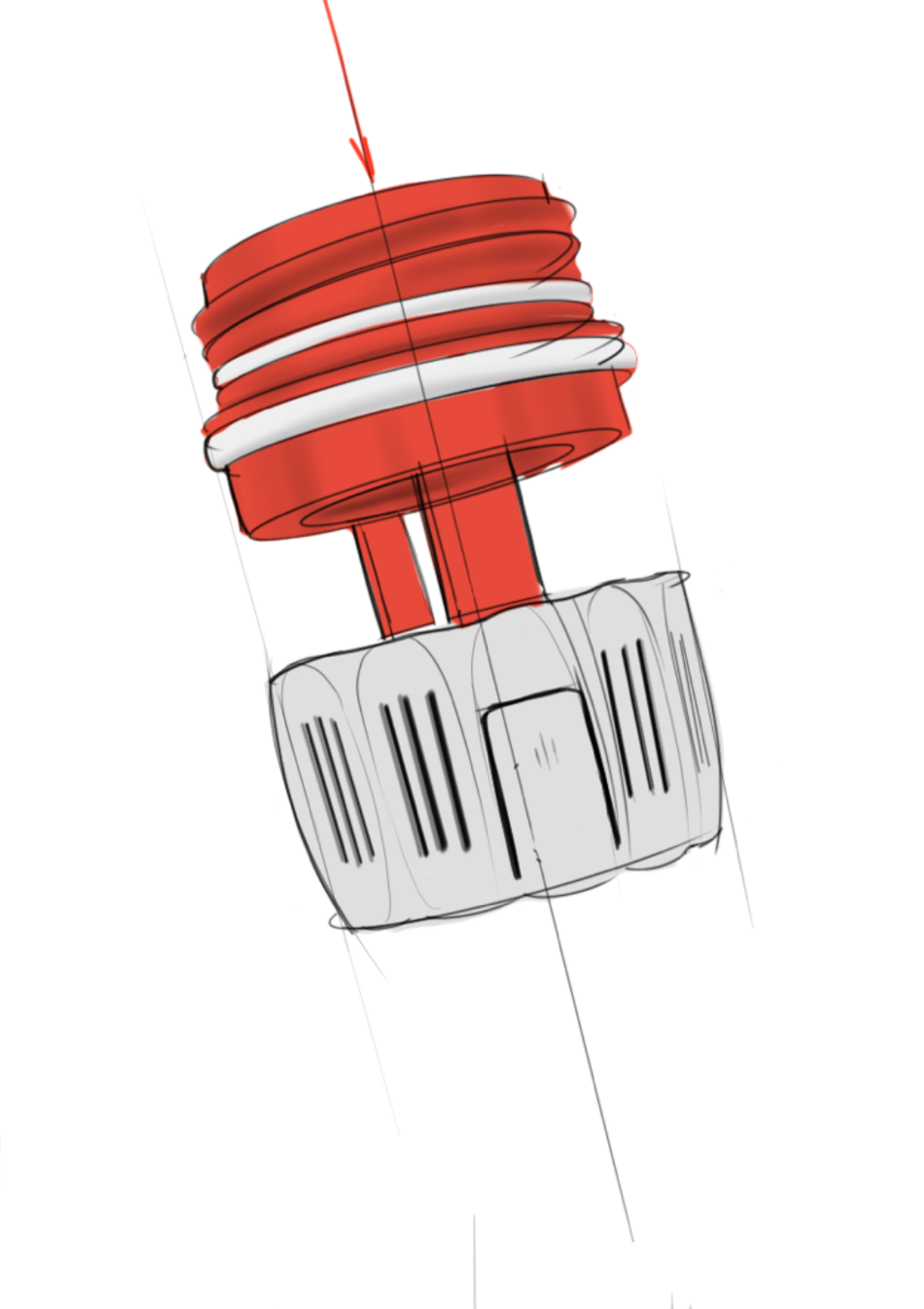

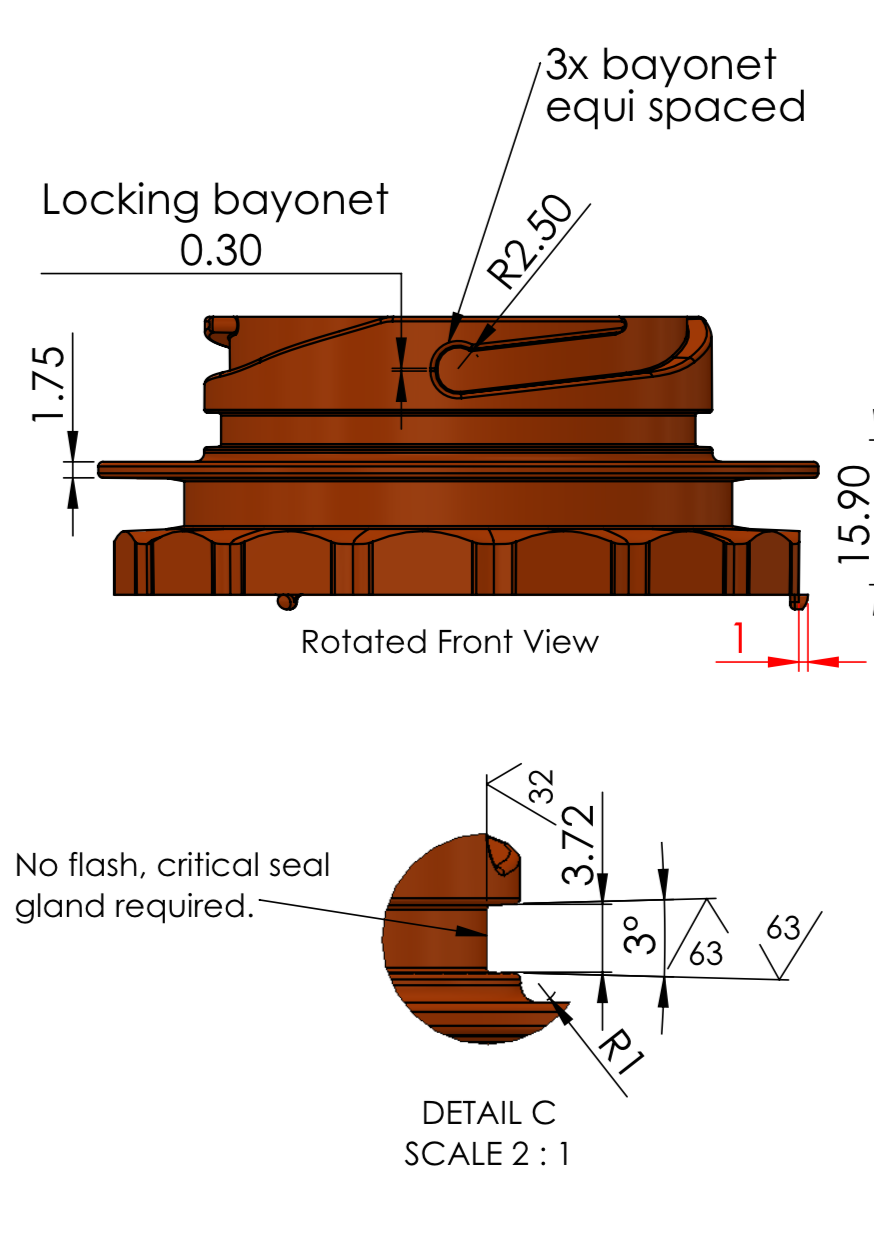

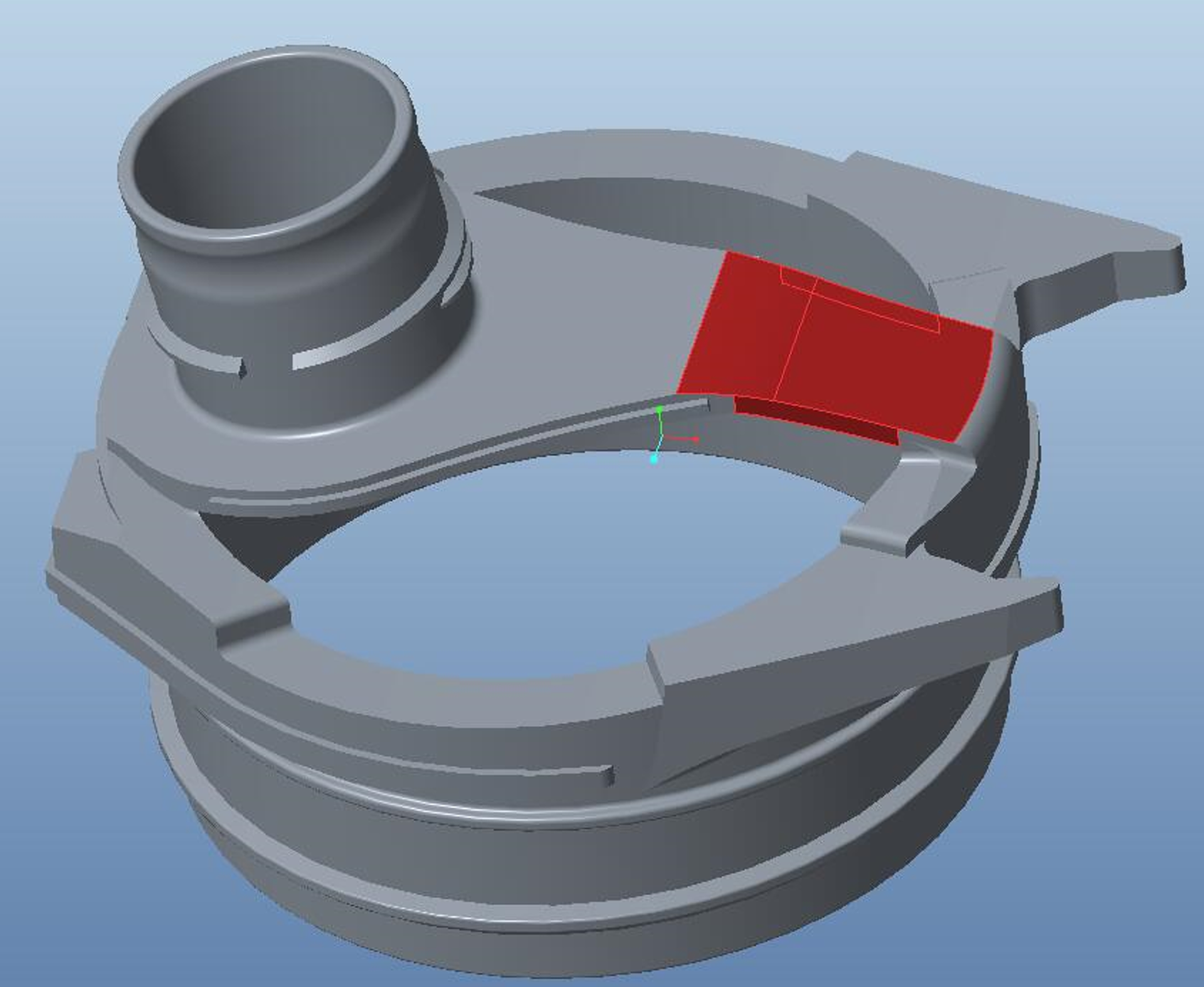

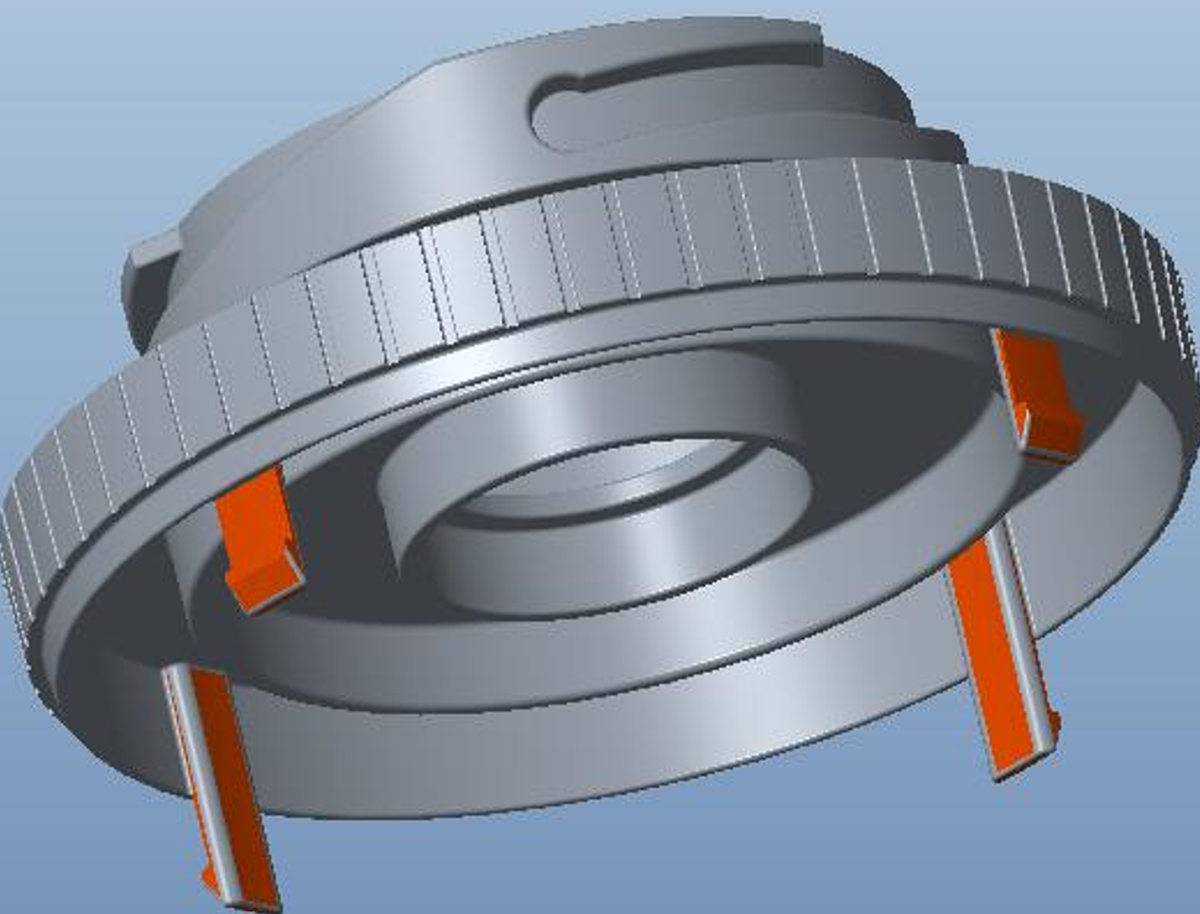

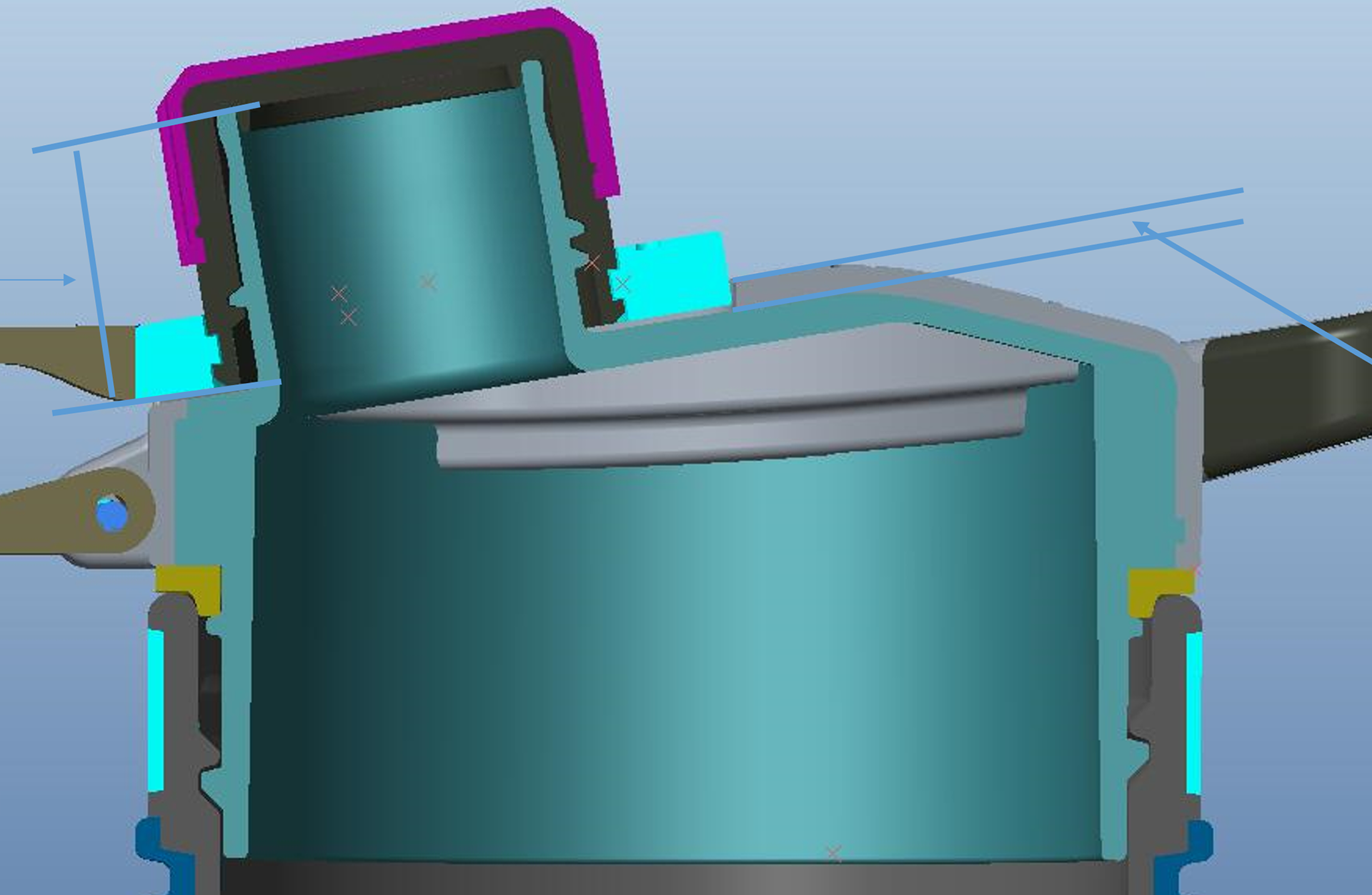

To address these issues, we patented a new lid that separates the pressing and drinking surfaces, and a custom bayonet for simplified filter swapping.

Manufacturing

Durability drop testing and filtration quality assurance were done in early-stage development to ensure things like pleat optimization didn't cause the filter to fail. Critical seals were tested to failure and optimized before tooling was made to save time and money as early in the process as possible.

Pre-production transparent prototypes were built to assess the new filtration media pleat density assembly procedure. Detailed QAQC drawings ensured each prototype met these standards.

I worked closely with multiple factories going through many DFM rounds to hit mass production on time and under budget.

Glue assemble procedure

Cap undermold DFM

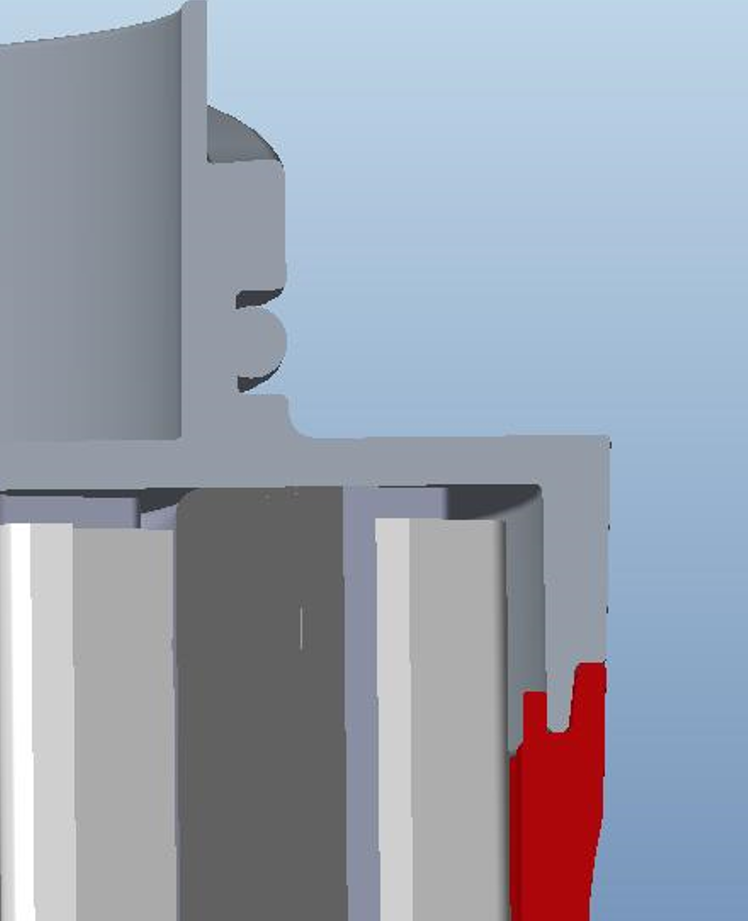

Filter lap joint

Filter cap clip DFM

Filter section fit

Topo overmold

Filtration testing

Results

- 3x faster filtering & 60% less user force required to filter

- 2x filter life and a redesigned structural core made the system last longer

- Simple & secure filter swap experience

- Zero contamination risk lid

“The GeoPress Purifier is the pinnacle achievement in our global mission to provide safe drinking water and surpass the limitations of filters and UV solutions, offering a true alternative to purchasing single-use plastic water bottles, which ultimately end up in landfills or polluting our oceans."

- Andrew Weber, Grayl President -

Awards and recognition

Patents

User research • Ergonomics • Industrial design • Mechanical design • Manufacturing validation • Volume production