Design a kayak that ...

Is lighter

Is faster

Is simpler

Can do donuts

Can fit in a check luggage bag!

Background

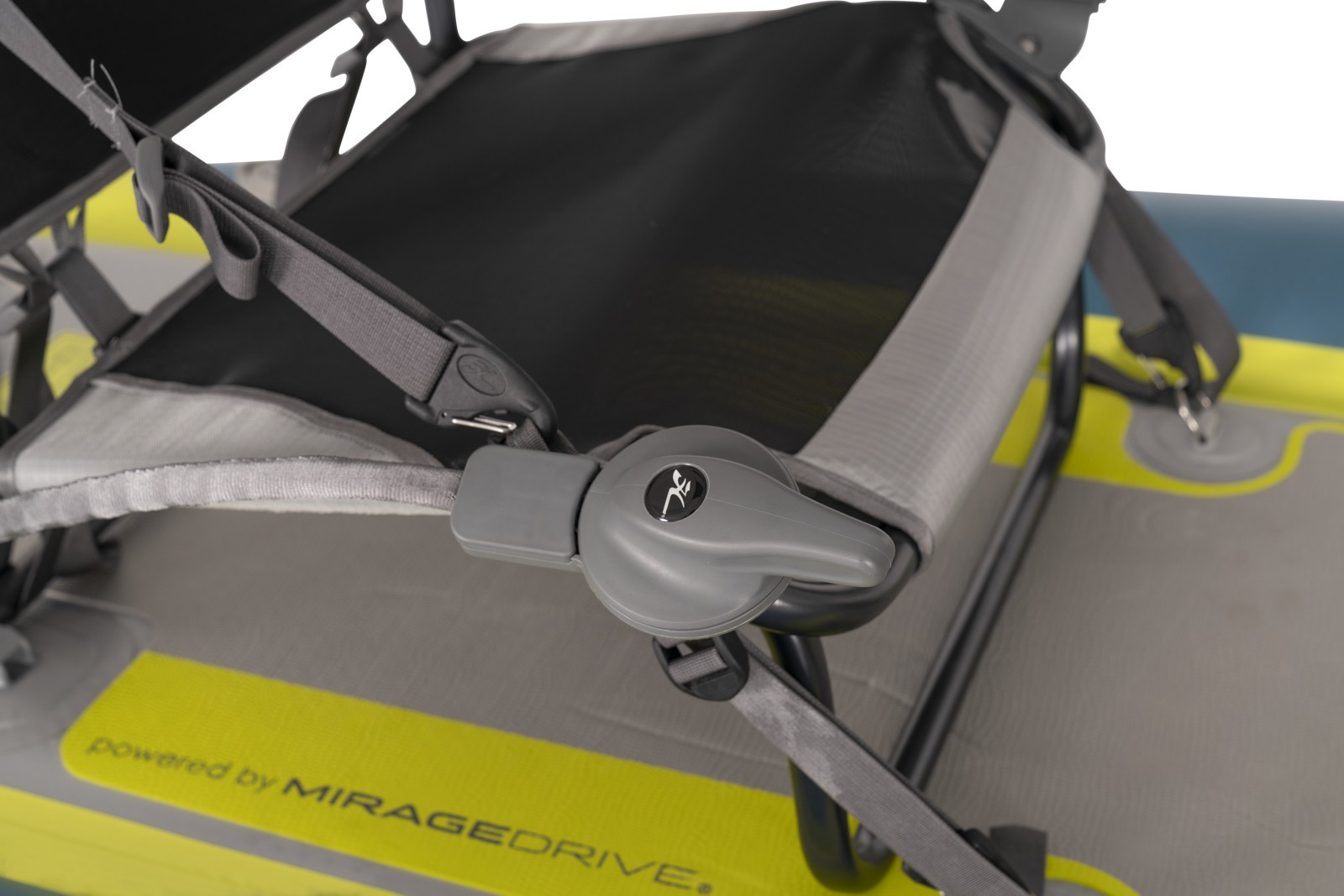

The iTrek series stands out as the only fin-driven inflatable kayaks available in the market. The ultralight drop-stitch hull combined with the MirageDrive kick-up fins and patented removable steering make it the ultimate lightweight kayak solution.

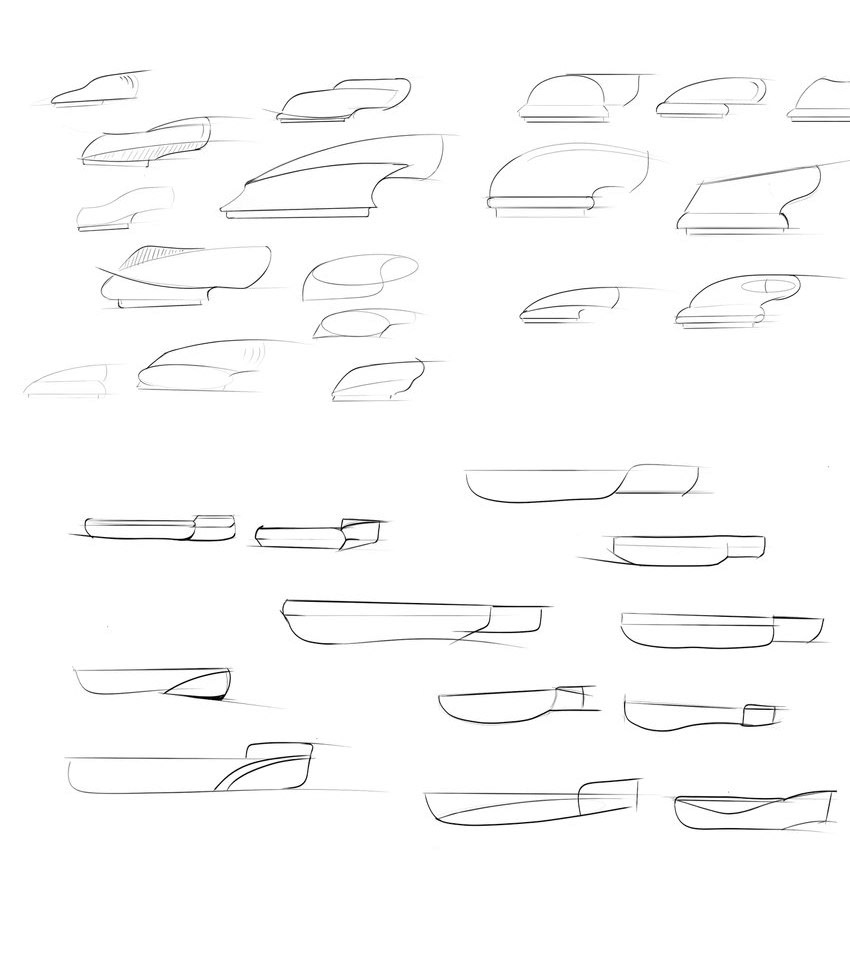

I responsible for the design, engineering and implementation of the removable steering system. I took it from concept to production working with the team to integrate it into a revolutionary product experience.

Steering on a dime

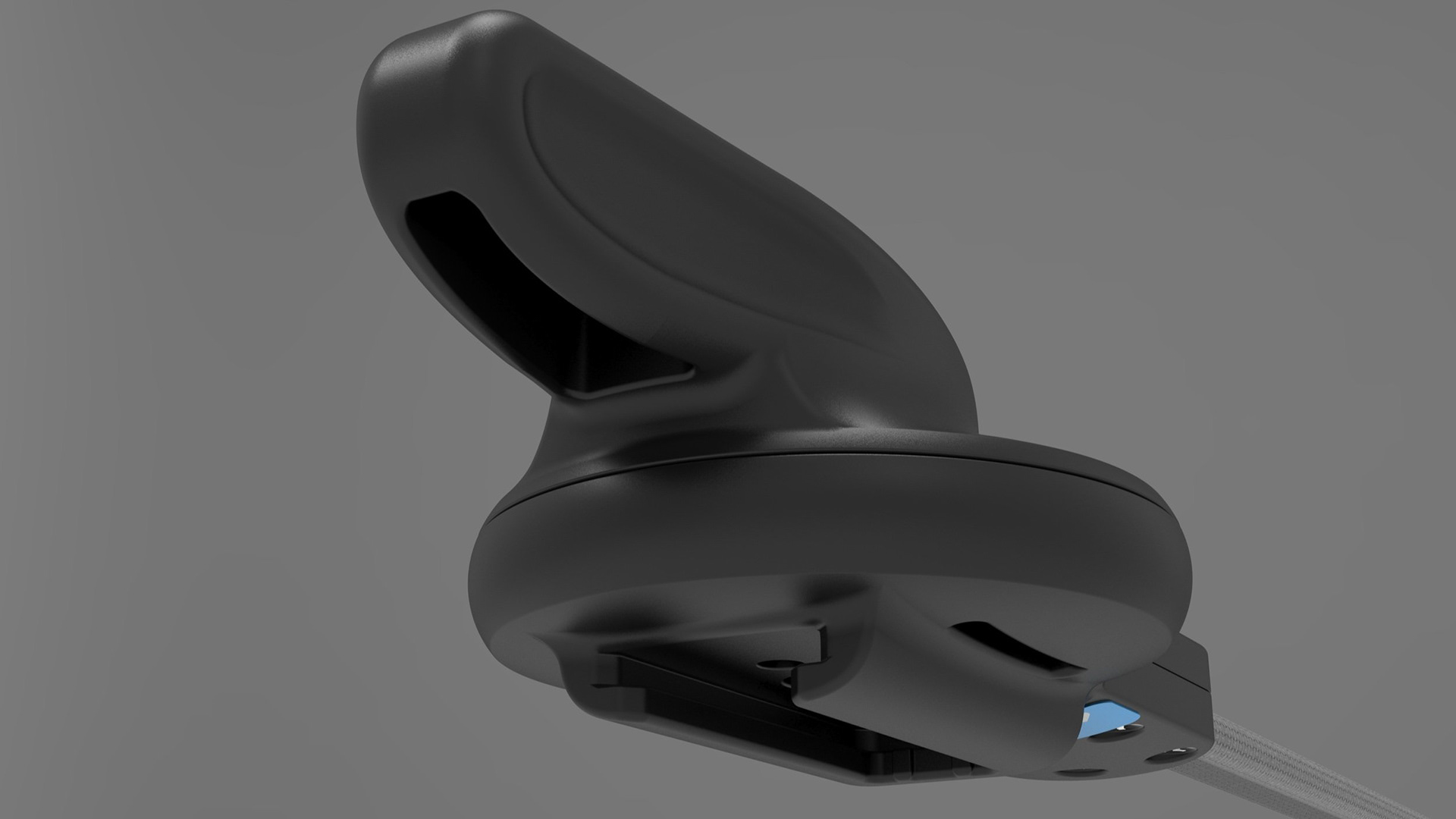

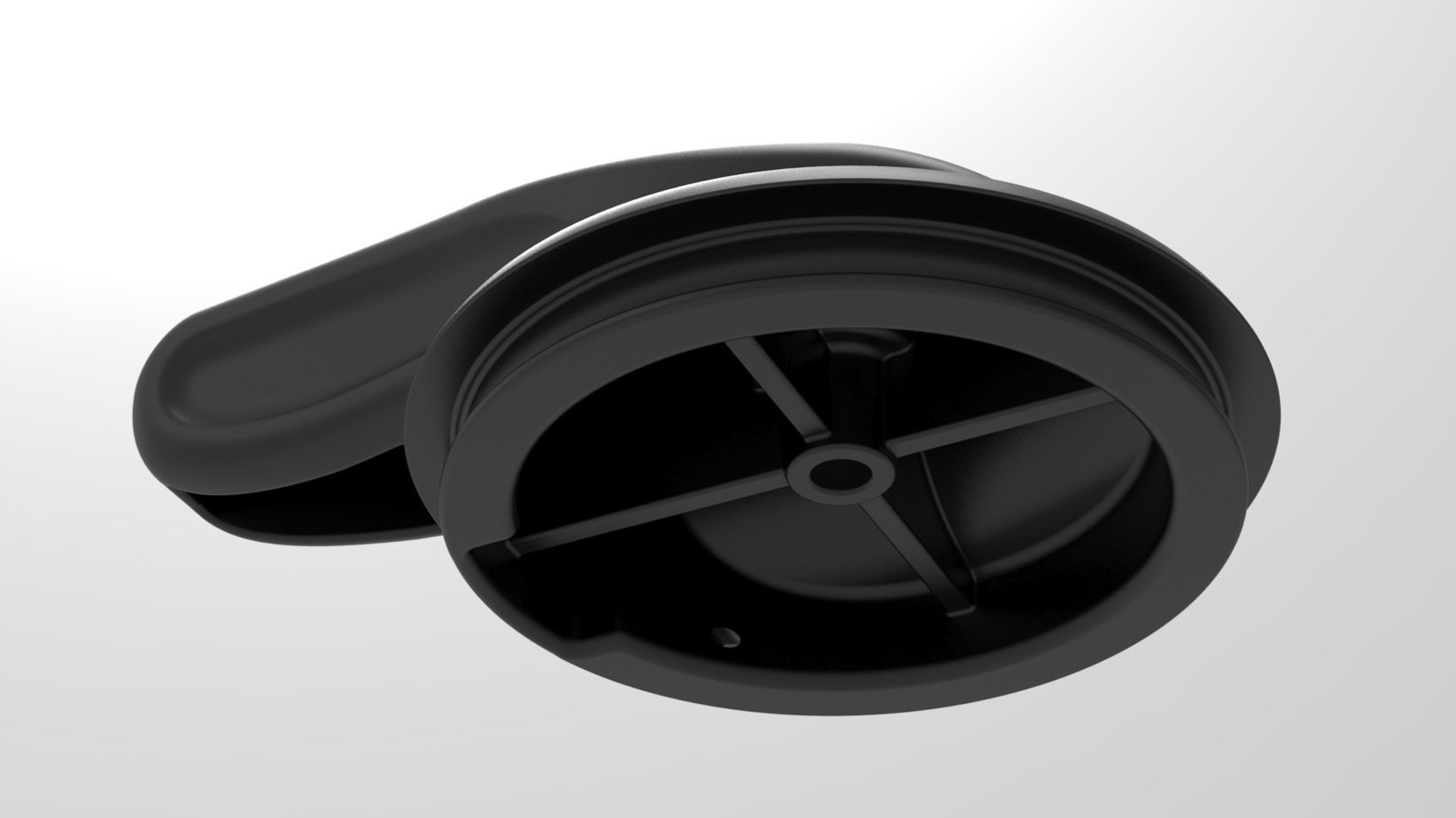

The patented (US11305858B2) removable steering allows any of these kayaks to turn within their own length. A carefully balanced rudder and compression tube cable management make for a smooth and nimble turning experience. A single line over-center mechanism deploys/retracts the kick-up rudder blade.

Prototype development

The rudder blade pin has a shear point in it to avoid breaking the rest of the rudder design. It only breaks under severe force, the benefit of stainless-steel cables and compression tubes over traditionally used nylon line is that there is next to no stretch over time meaning users may never need to adjust the rudder lines.

This design set a new standard for ease-of-manufacture, ultra-low friction steering and a rudder system with the largest turning angle, giving any inflatable the ability to turn within its own length.

Testing

One of the best ways to test the durability of the steering, seat and drive assemblies was to take it out on a 6ft surf day and see how it steers when it matters most. This forced sand and saltwater into the system as well as testing the ultimate tensile strength of the entire system under extreme load conditions.

We leant a lot about where the part was weak and made changes to accommodate. Testing the worst-case scenario for us is often where we found the best pain points to improve our designs.

Shear pin testing

XL rudder mod

Up-Down invention worked!

Design details

We took care to label each configuration with different colors and decals so that the user can identify which model they have, we put marine grease in the caps of the cable tubes to prevent corrosion. We put a lot of effort into the ergonomics and user fit for the project.

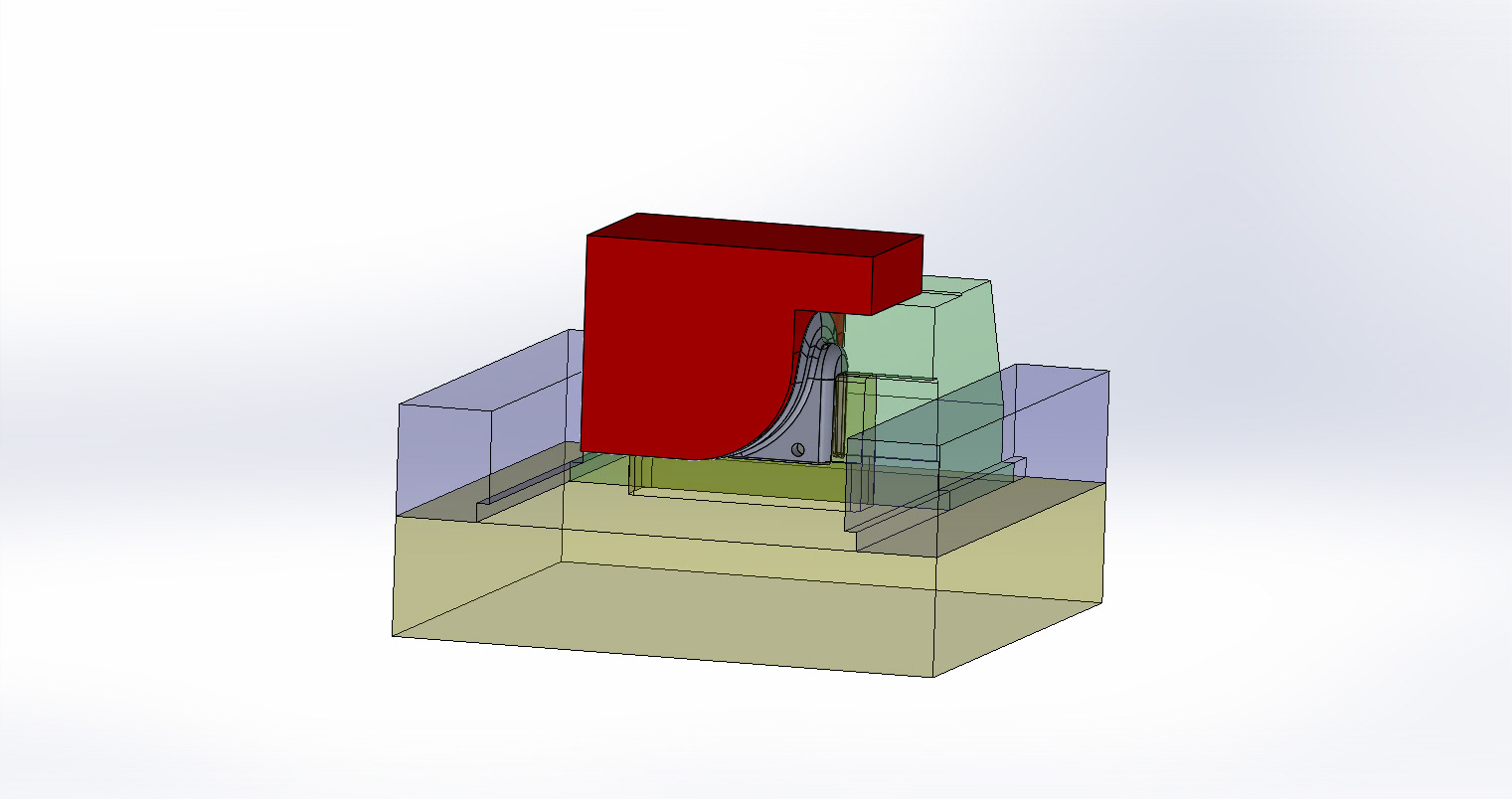

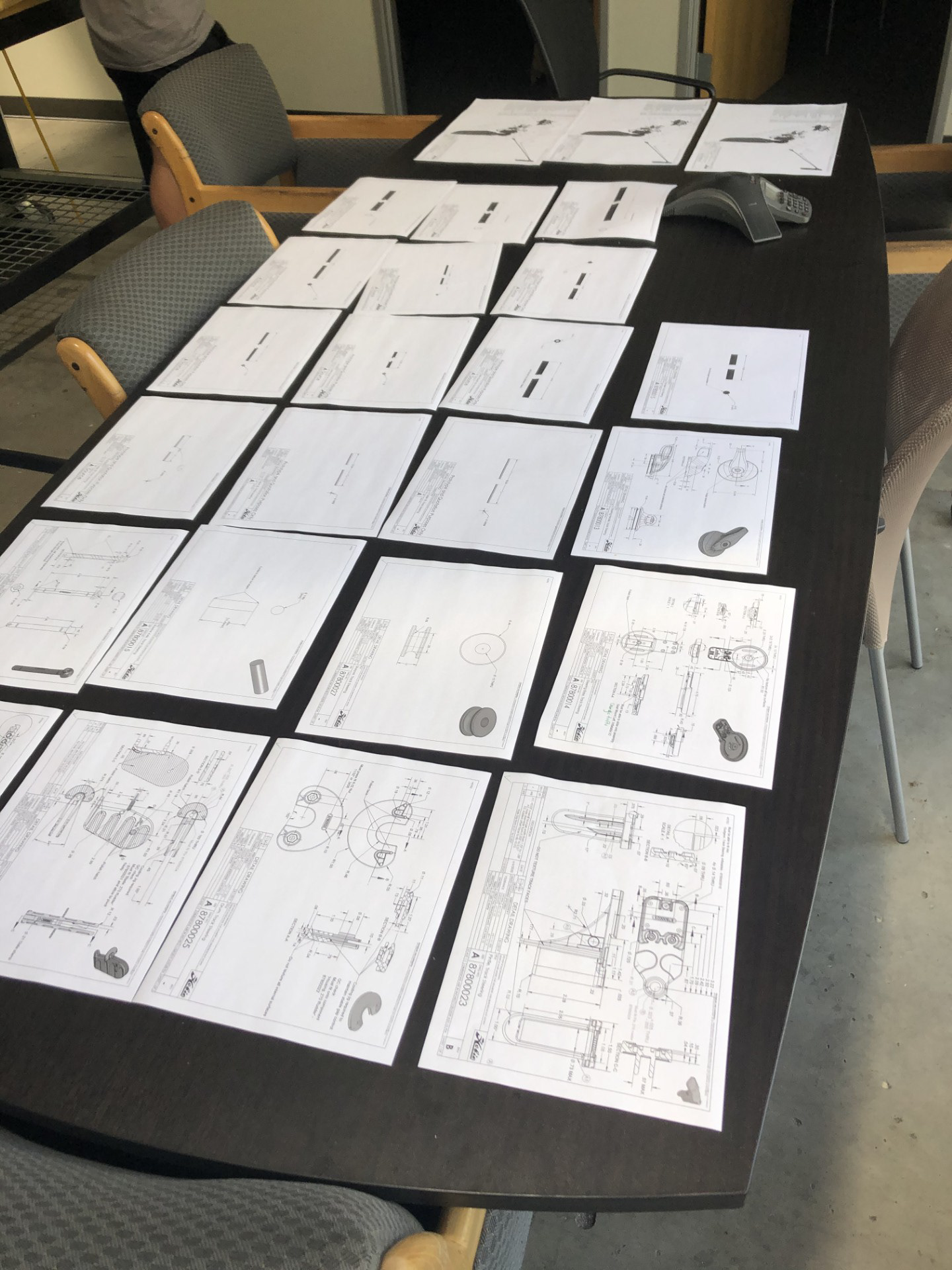

Manufacture

We worked hard to coordinate a global supply chain of parts. We chose to make certain parts directly with the inflatable vendor to keep a quick feedback loop for parts that share a fit requirement. We expanded our DFM work to make the designs work no matter who the vendor was. This required a good amount of QC drawings and GD&T engineering standards.

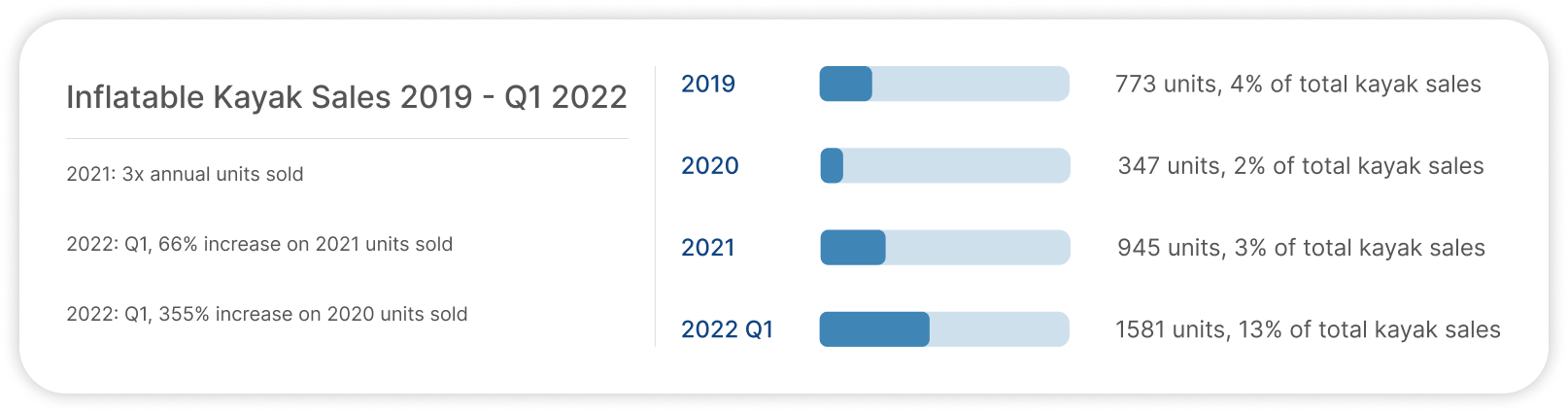

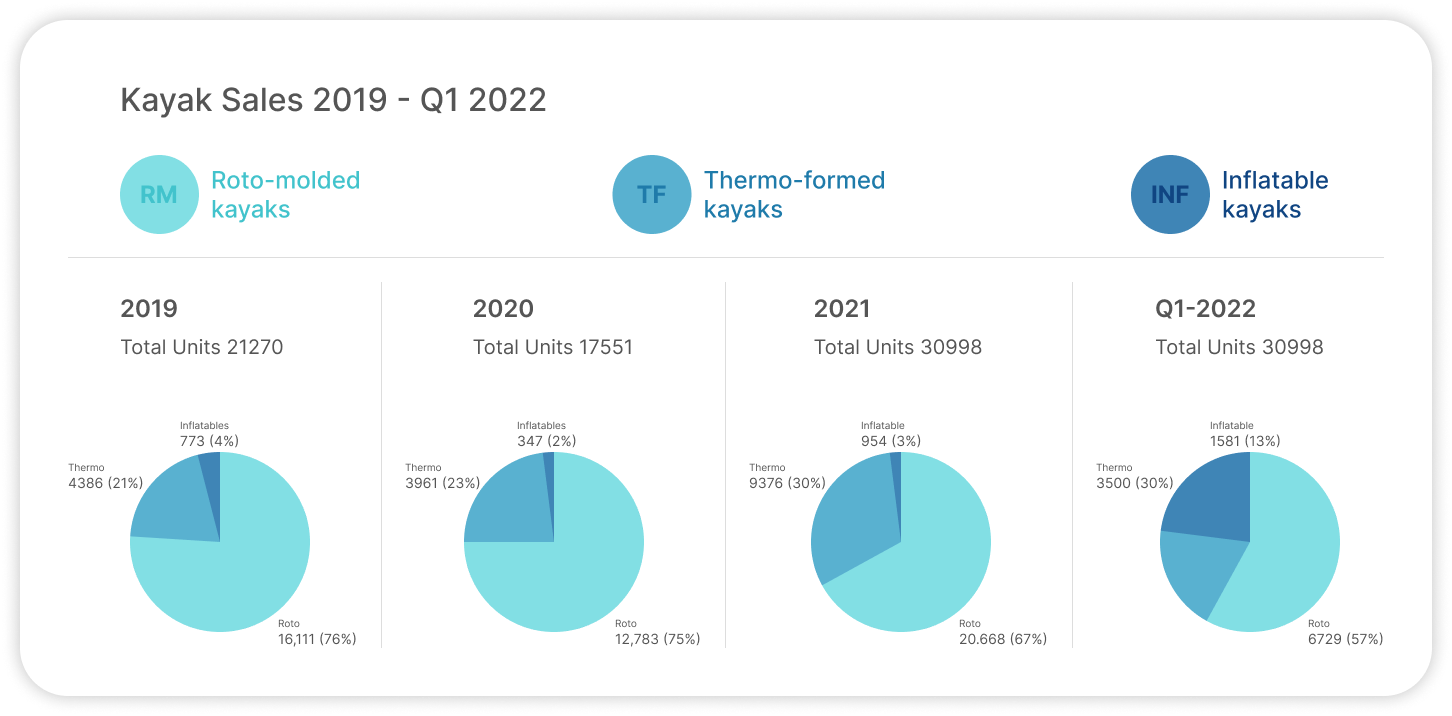

Results

With the introduction of the iTrek series, we effectively doubled sales numbers from 2019-2022. This continues to be a large source of revenue for Hobie going forward in a competitive market. Our customers were incredibly happy with the quality and finish of the new designs noting the revolutionary steering mechanism.

Involvement: Concept development • Mechanical Design • Industrial Design • DFM • Patent protection

Software: SolidWorks • Rhino • Keyshot • Adobe CC

Process: Sketching • 3D Printing • Injection Molding • Wire forming