Eclipse V2

Eclipse V2 was my first complete craft as lead designer. I took the findings from first Eclipse project and applied it to a new hull construction method. With thermoforming, we enabled a whole new level of fit and finish, detail work was done on the rocker (top and bottom profiles on a side view) to allow the Eclipse to carve through the water while turning on a dime. The steering system was developed to be a simple and easy user interaction.

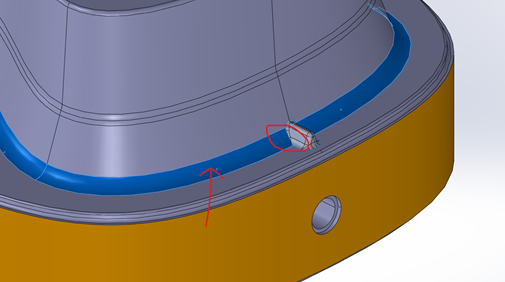

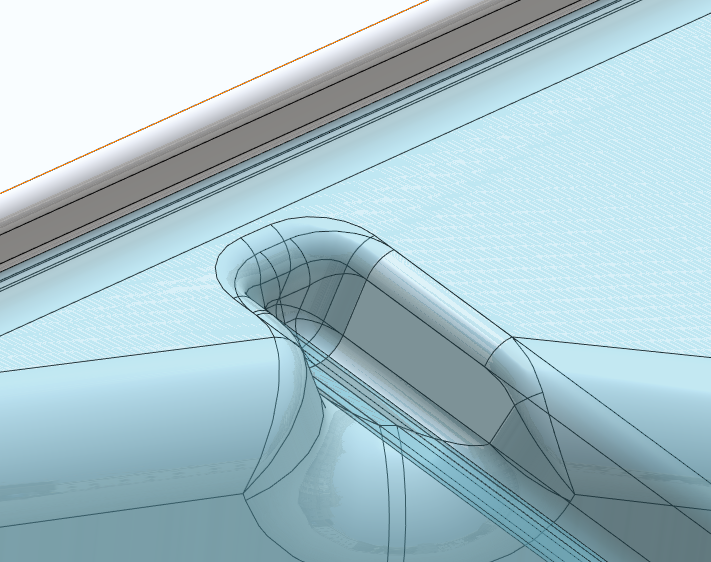

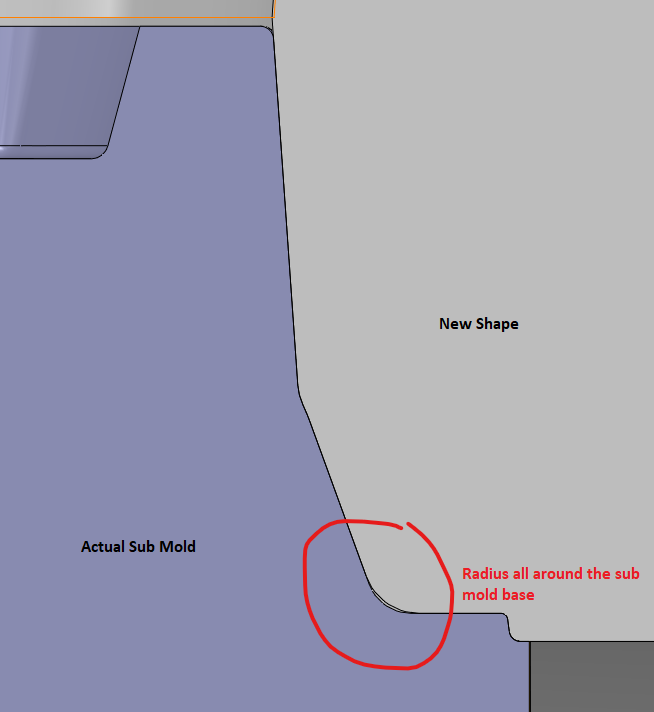

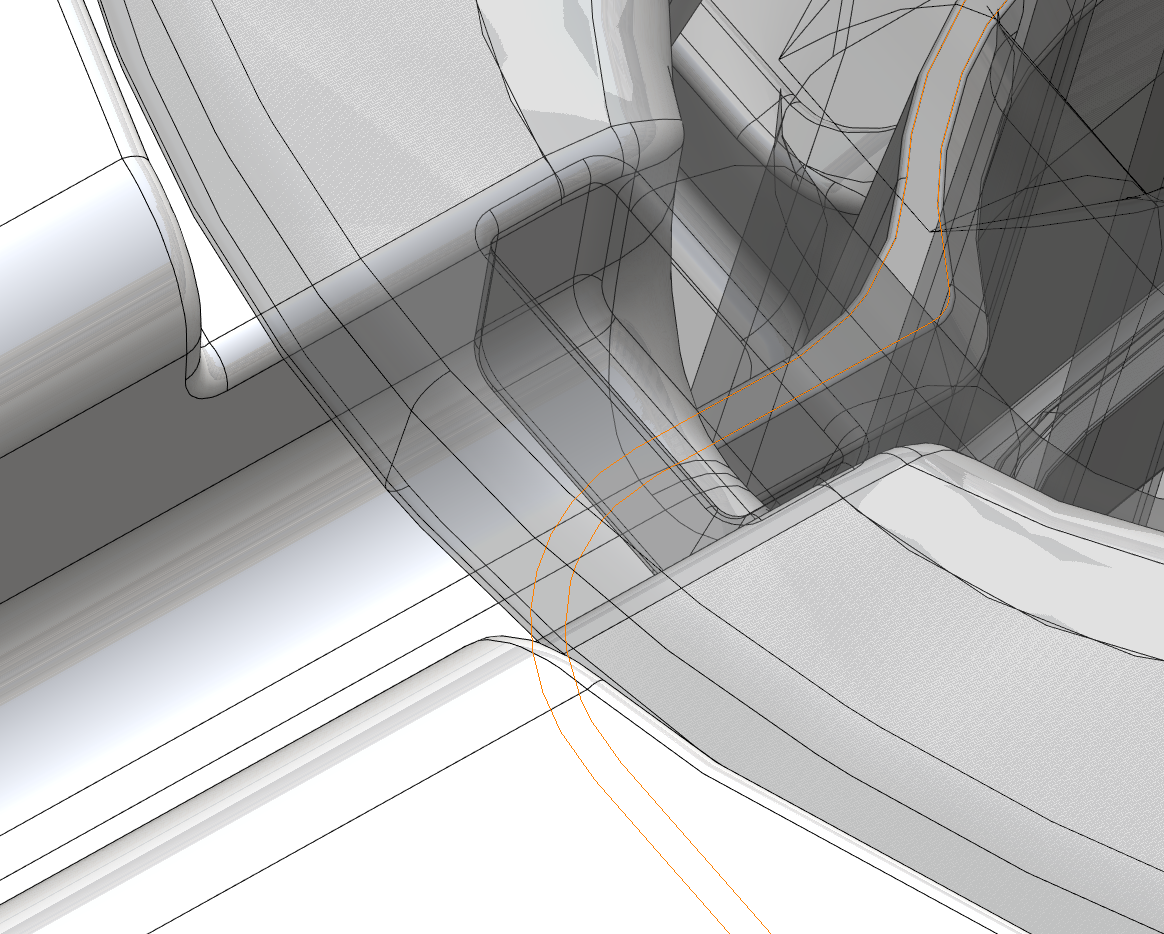

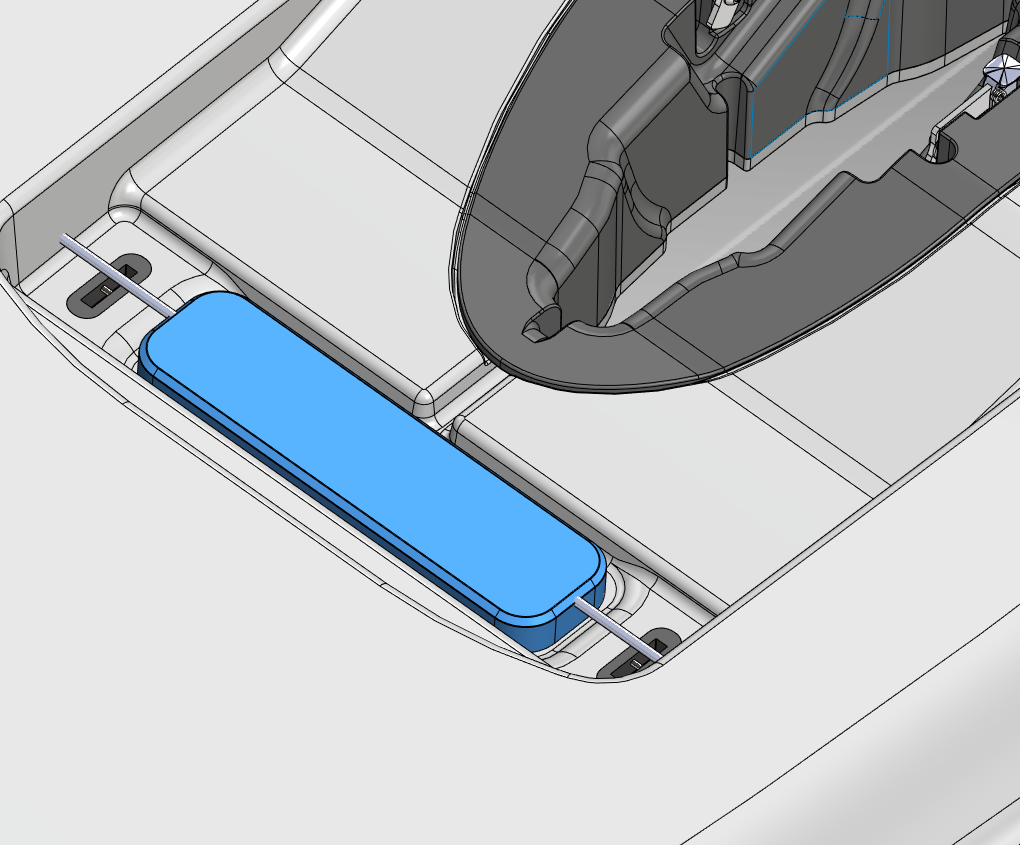

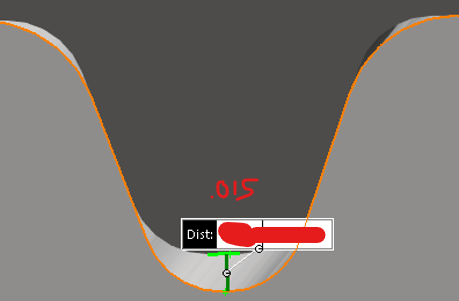

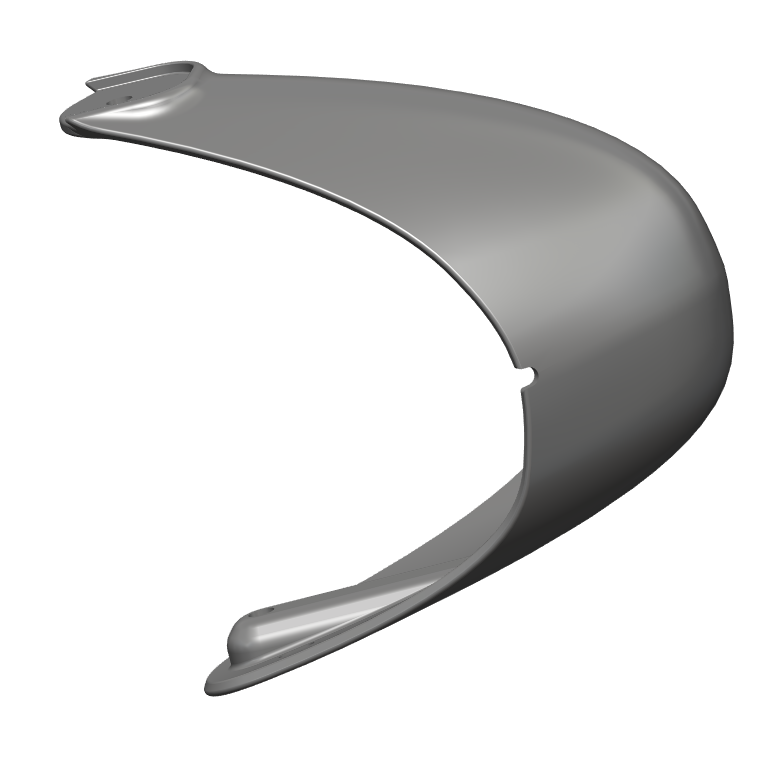

CAD for manufacturing

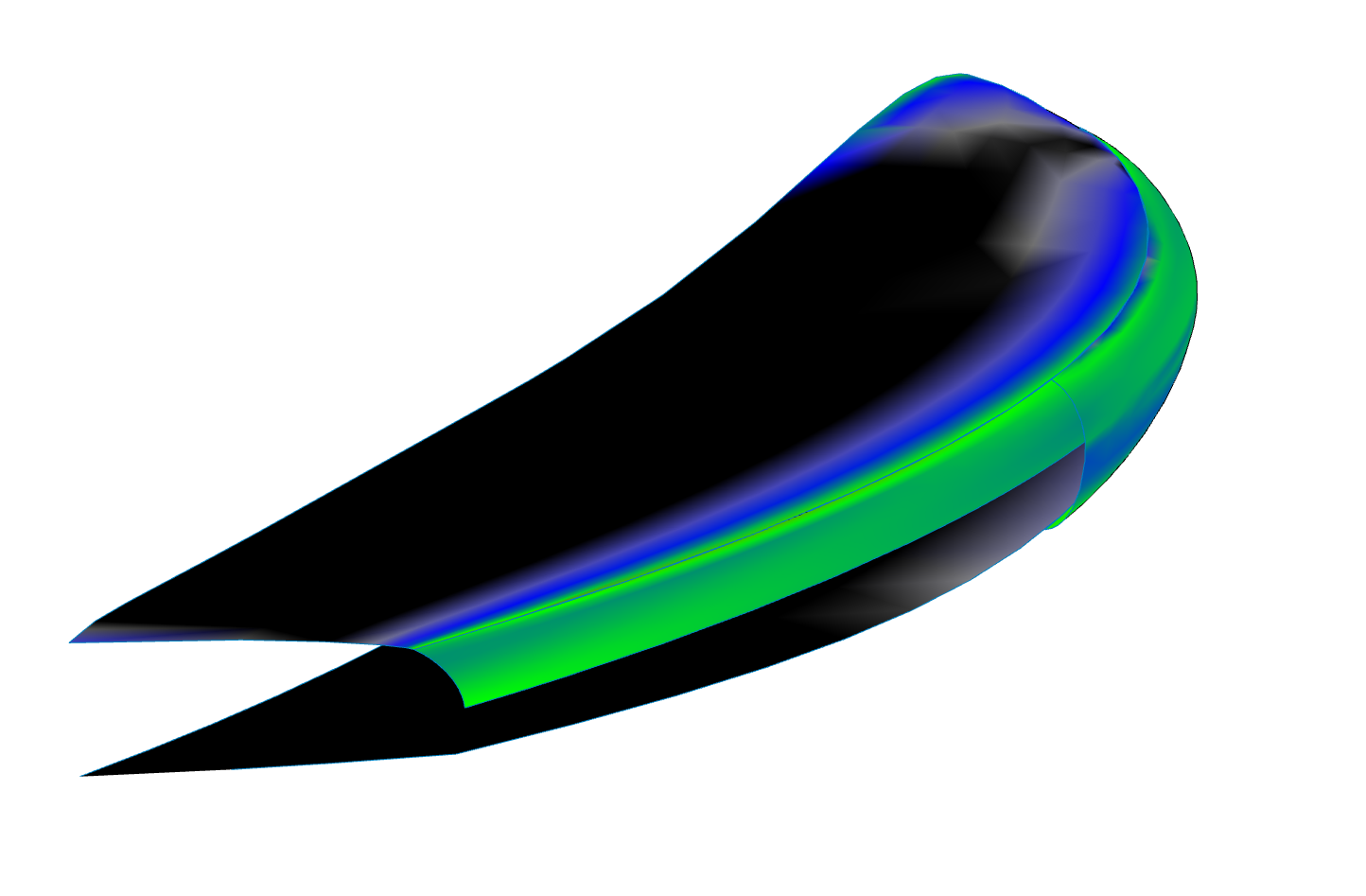

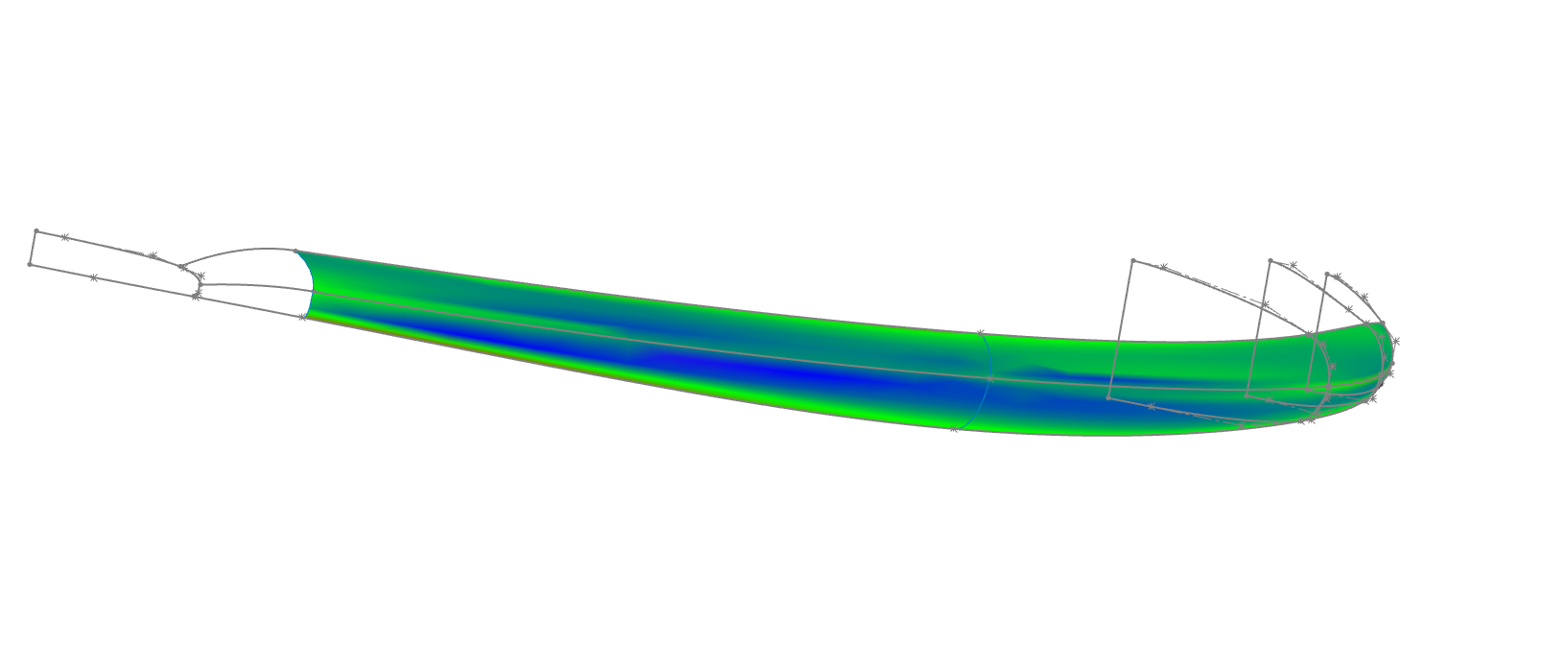

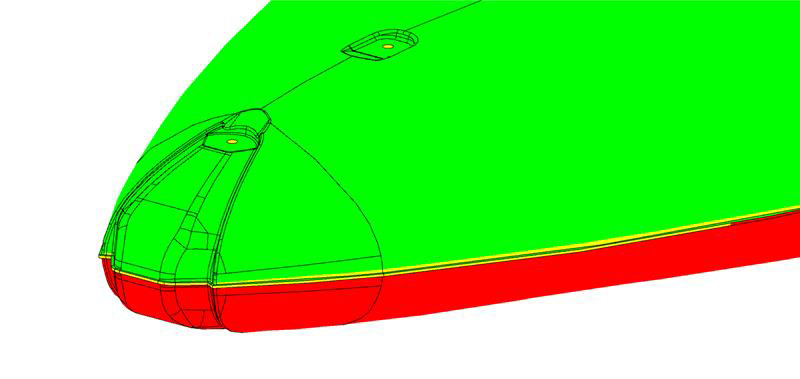

Understanding thermoforming limitations was imperative to creating a flexible and adjustable surface model. Every detail from surface split lines to offset curves for the nose cone was implemented into the modeling strategy.

Tolerance well fitment

Nose cone surfacing

Rail curvature analysis

Parting line draft

Megawell

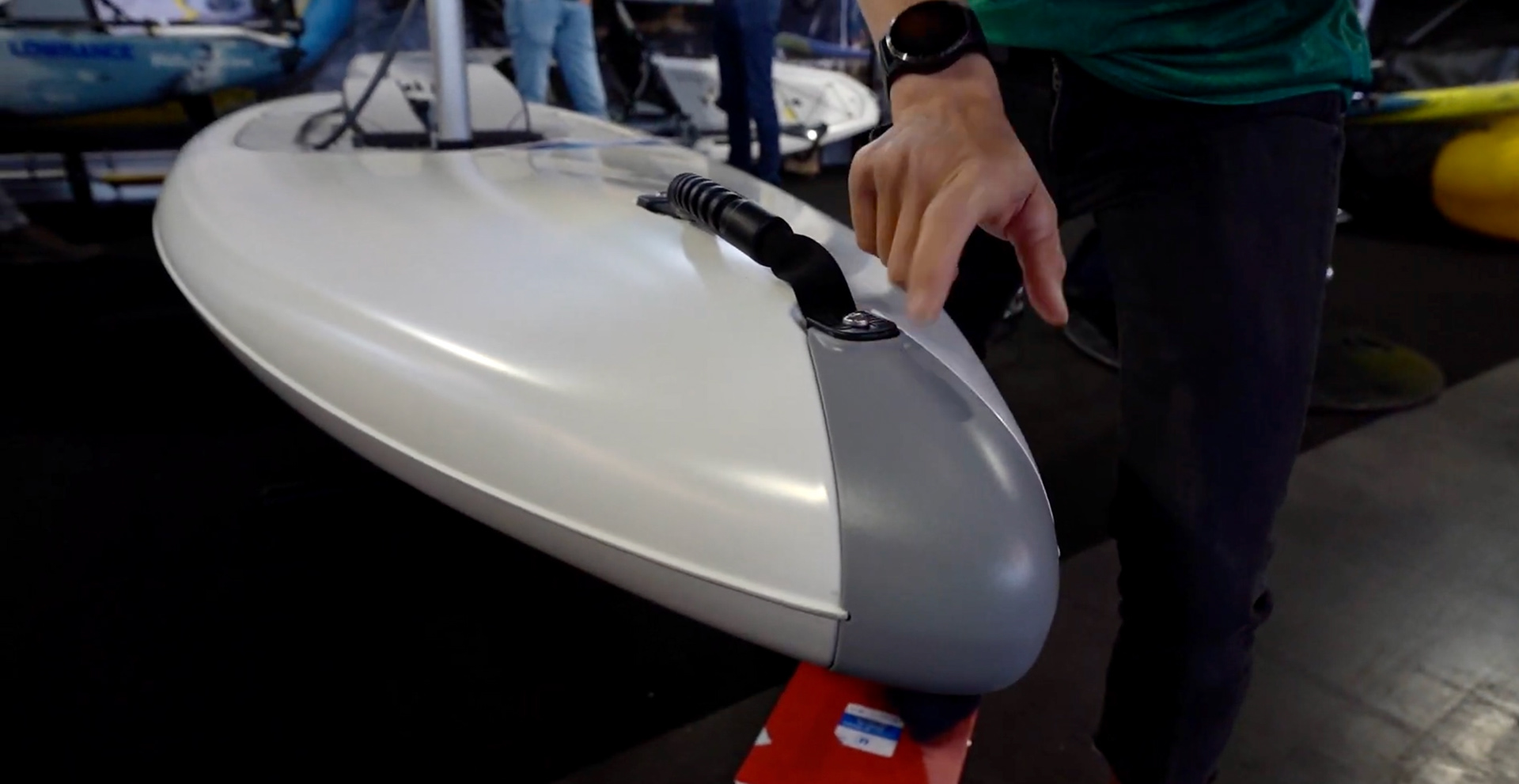

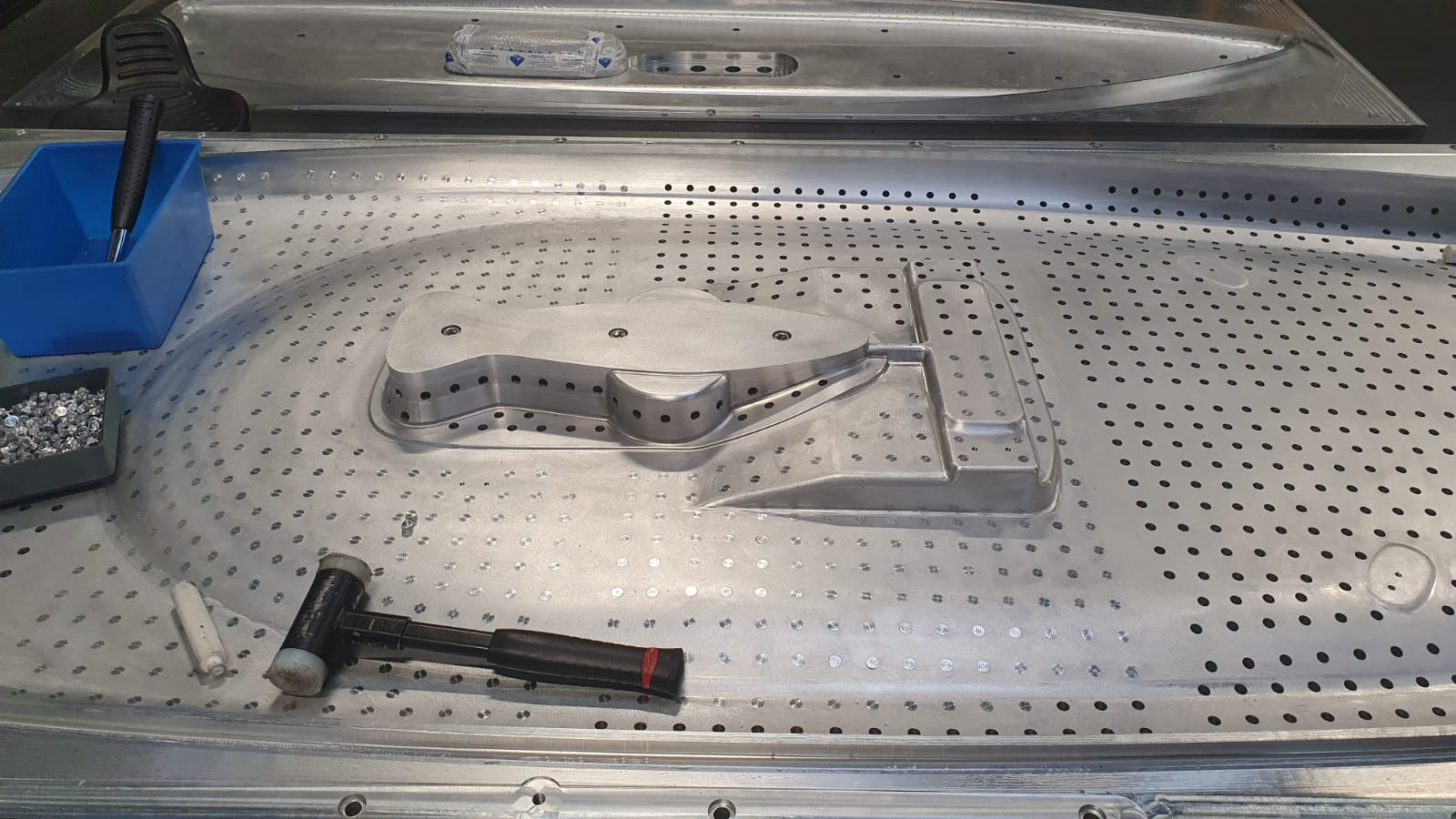

We had to design an all new mirage well for the board to include the steering handlebar. It had to carry immense loads of the user applying force with a large lever arm. I also designed a new nose cone that worked for thermoforming radius limitations. It allowed the user a bumper to guard preventing damage to the hull.

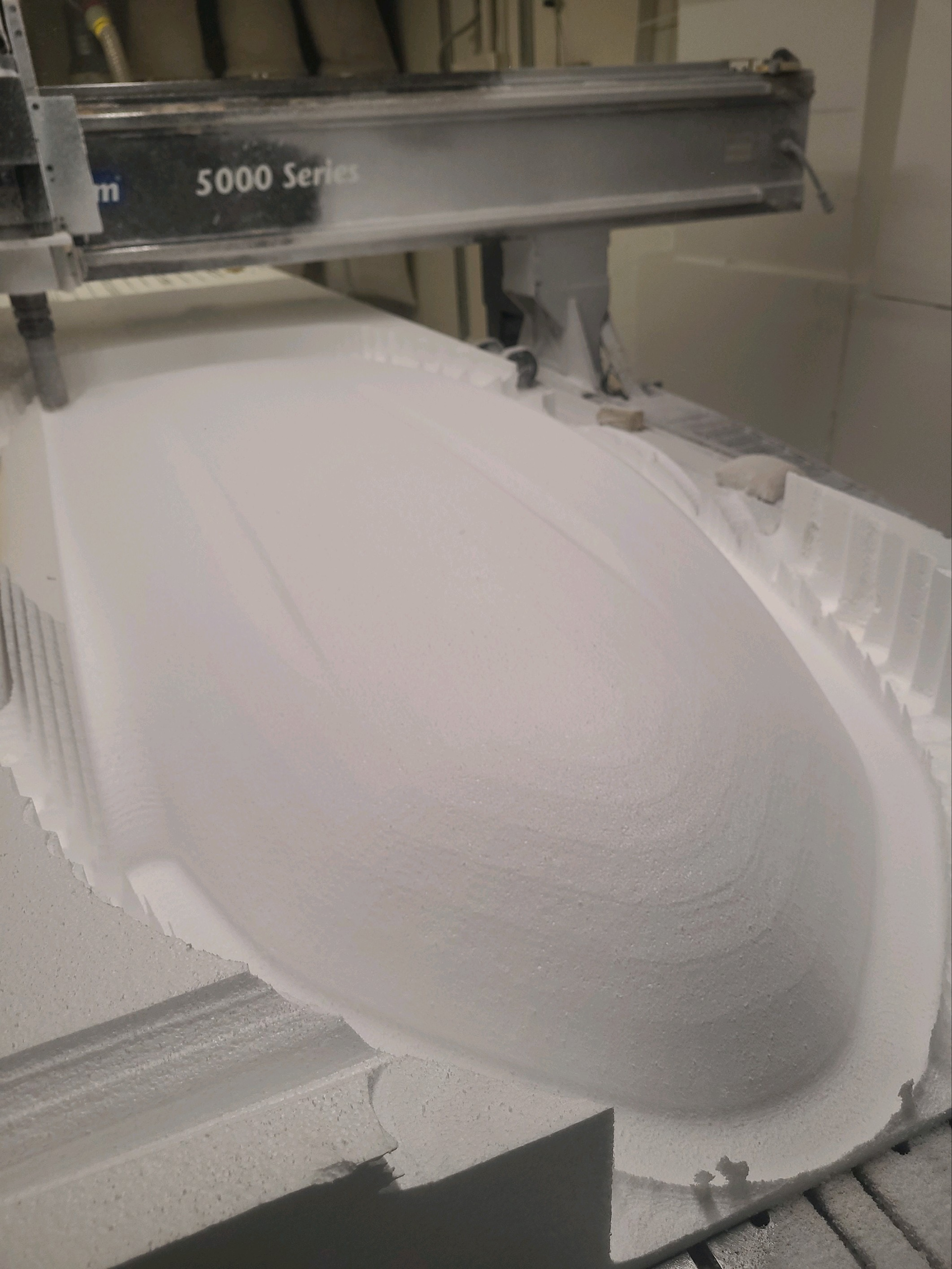

CNC prototype

Injection well testing

3DP nose cone tolerance check

Initial hull EVA prototype

Nosecone injection mold

Nose cone thermoform

Tooling

We milled a giant block of aluminum using my CAD, we built in removable sections for repair. We had to build two exact match tools: one for the foam core and one for the thermoform outer skin.

Hull Design • Steering Assembly • A-class surface model • Engineering design • Injection Molding • Advanced Thermoforming

Inflatable Eclipse

The Inflatable Eclipse built on the work done during the iTrek series. Using our drop stitch inflatable material to create a stand-up pedal board that customers love. It allows all of the benefits of a standup paddle board without the hardship of trying to go into a strong wind.

Hull Design • Steering Assembly • Mirage Well